October 19, 2024 · Blog

Introduction

Fanuc system small teaching CNC lathe is a combination of Fanuc's advanced CNC technology and small lathe design of teaching equipment, mainly used for teaching and training, to help students and trainees master the operation and programming skills of CNC lathes. Here's a closer look at it:

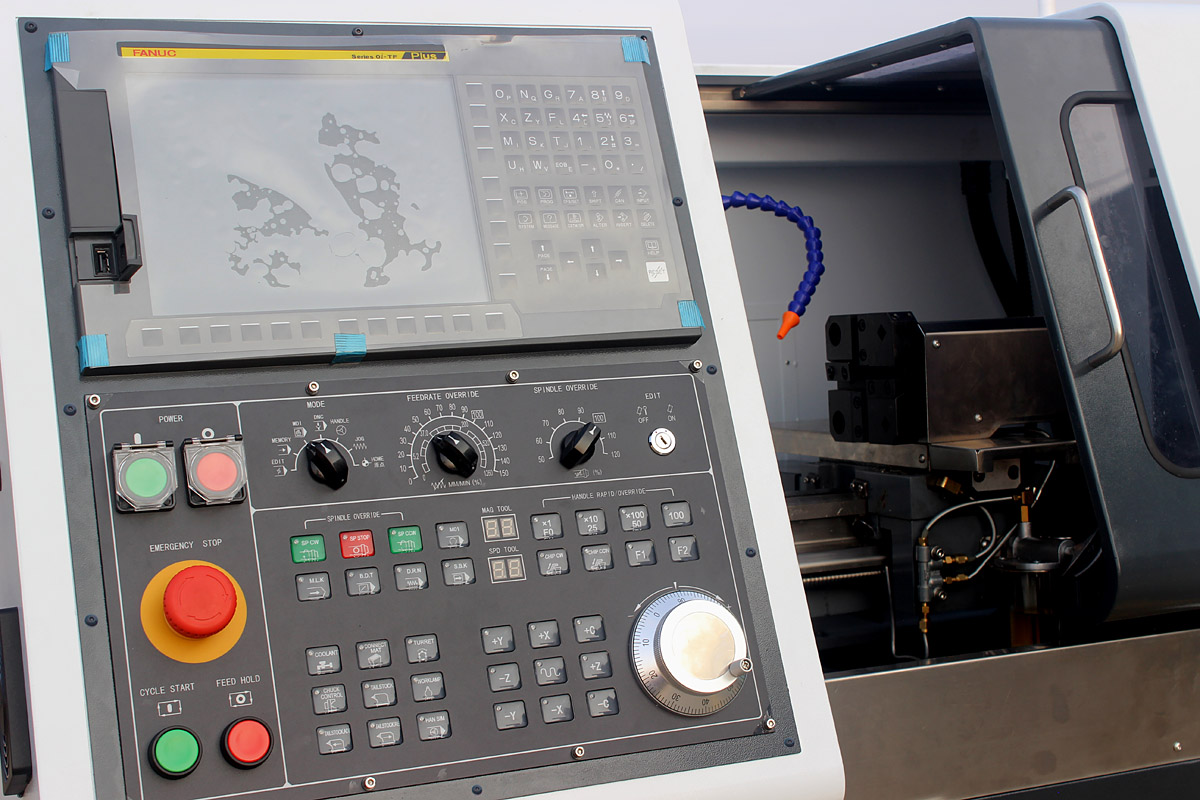

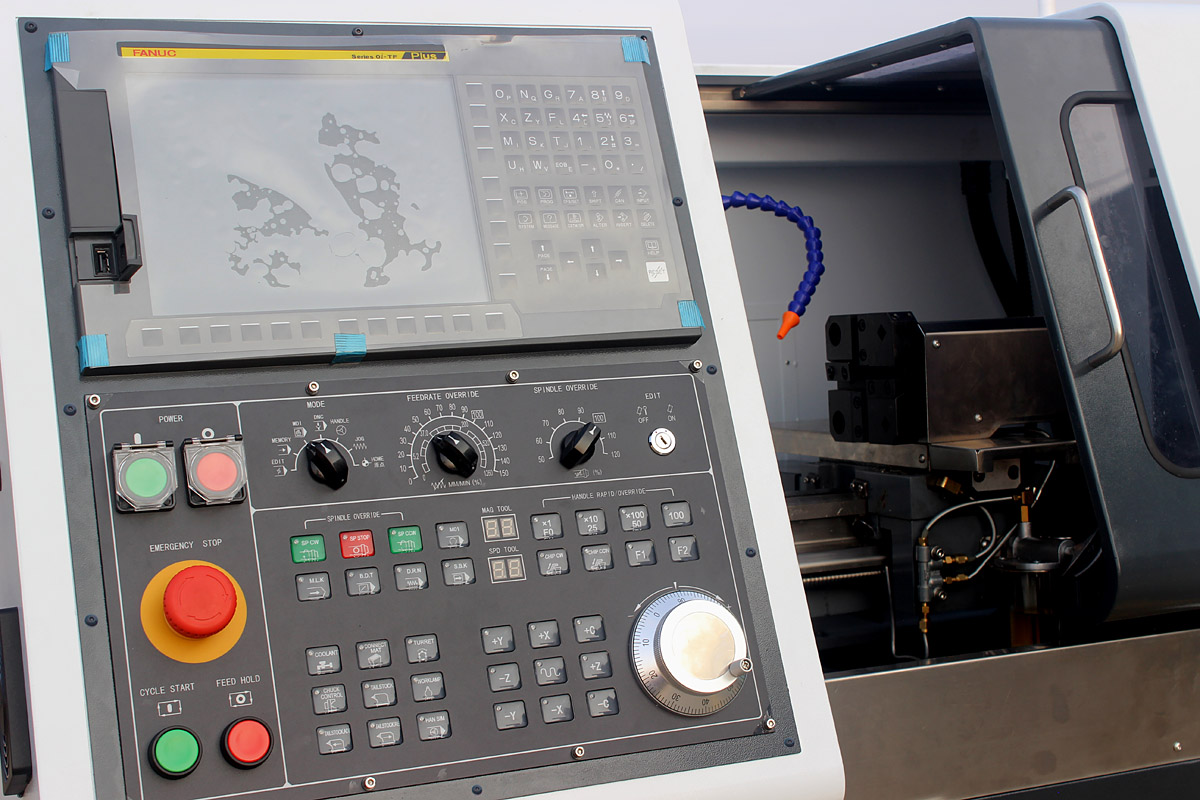

CNC210 Compact Educational CNC Lathe with FANUC Controls

1.The characteristics of the equipment

State-of-the-art Fanuc CNC system:

The use of computer control and digital programming technology can greatly improve the production efficiency and quality level of traditional lathes. Through numerical control technology, according to the digital instructions input by the machine operator, the workbench and tool holder and other components are automatically accurately positioned, and the control of automatic processing and machining accuracy is realized. It supports a variety of programming languages and processing modes, such as G-code, M-code, etc., and is compatible with a variety of CAD/CAM software, such as MasterCAM, UG, CAXA, etc.

Compact design:

The geometric size of the appearance is small, usually the length, width and height are within a certain range, which is suitable for use in limited spaces such as classrooms or training rooms, and occupies a small area, which is convenient for flexible layout and movement.

High precision and stability:

It has high machining accuracy and stability, which can meet the needs of teaching, and has high repeatability and positioning accuracy to ensure the consistency of processing quality.

Easy-to-use teaching interface:

The operation interface is intuitive and easy to use, which is convenient for students to learn and operate, and is equipped with detailed operation manuals and guidance videos to help students get started quickly.

Perfect security protection measures:

It is equipped with safety protection settings such as safety switch for protective doors, chip protective covers, and circuit leakage protection to ensure the safety of students during operation. The high transparency of the machine tool cover housing is convenient for students to observe the structure and working status of the machine tool.

Small CNC Educational Lathe of FANUC 0i-T Plus Controls

2.The function of the equipment

Automatic processing function: according to the preset processing program, the machining process of the workpiece is automatically completed.

Manual adjustment function: Manually adjust the position of the tool and workpiece for finer machining operations.

Real-time machining simulation function: CNC software has real-time machining simulation function, which can simulate the actual machining process and help students better understand the machining principle and operation process.

CNC210 Small CNC Educational lathe laborator

3.Application scenarios

Teaching and training: The equipment is suitable for all kinds of educational institutions, training institutions and skills training centers, and is used to train CNC lathe technical personnel.

Teaching experiments: It can be used for experiments and research on CNC lathes to help students master the working principles and operation skills of CNC lathes.

YORNEW's CNC210 Small CNC Educational lathe

4.The price and purchase suggestions

The price of Fanuc system small teaching CNC lathes varies depending on the model, configuration, brand, and other factors. When purchasing, it is recommended to consider factors such as teaching needs, budget, and equipment performance. At the same time, you should choose a supplier with a good reputation and after-sales service to ensure the quality of the equipment and the reliability of after-sales service.

5.Maintenance and maintenance

In order to ensure the long-term stable operation of the equipment, the equipment should be maintained and maintained regularly. This includes cleaning the equipment, checking the connection of various components, lubricating transmission parts, etc. In addition, the accuracy of the equipment should be checked and calibrated regularly to ensure the machining accuracy and stability of the equipment.

To sum up, the small teaching CNC lathe of Fanuc system has the characteristics of advanced CNC system, small and compact structure design, high precision and high stability, easy-to-operate teaching interface and perfect safety protection measures. It has a wide range of application prospects in the field of teaching and training, and can meet the needs of teaching and processing.

YORNEW's CNC210 Small CNC Educational lathe

| Technical parameters |

| Turning diameter over bed(max) |

210mm |

| Chuck diameter |

100mm |

| Spindle speed |

300-1750r/min(control speed of G code) |

| Spindle through-hole |

26mm |

| Spindle mount |

MT4 |

| Spindle motor power |

1100W |

| X axis travel |

90mm |

| Z axis travel |

300mm |

| X/Z axis motor |

400W Servo Motor |

| The max moving speed |

4000mm/min |

| The max feeding speed |

2000mm/min |

| Control system |

FANUC 0i-T Plus Controls |

| MPG handwheel |

4 axis |

| Automatic tool change system(ATC) |

4 Tools (option 8 tools) |

| Tool dimension |

12*12mm |

| Tailstock taper |

MT2 |

| Tailstock sleeve diameter |

20mm |

| Travel of tailstock |

25mm |

| Positioning accuracy: |

0.02mm |

| Repeatability accuracy |

0.03mm |

| Power |

380VAC |

| Weight(NW/GW) |

280/320KG |

| Overall dimension |

1200*700*1300mm |

| Packing size |

1200*860*1500mm |