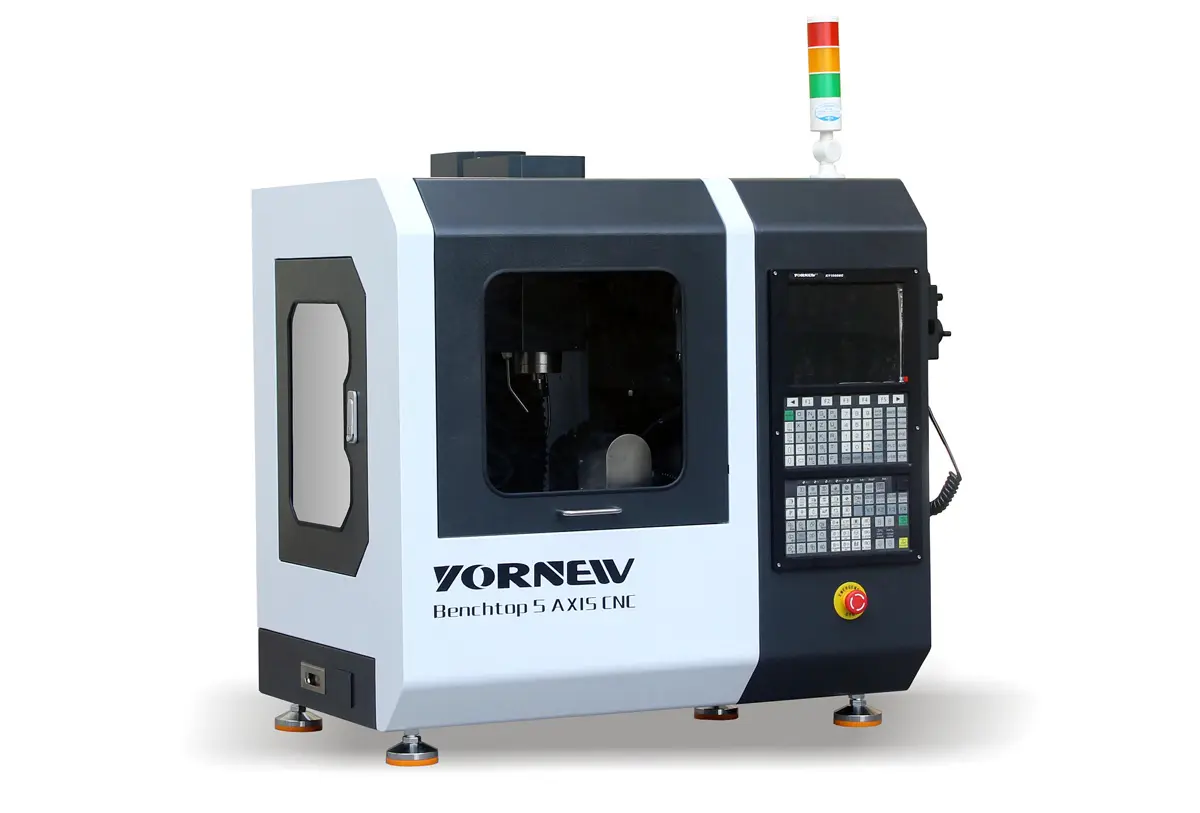

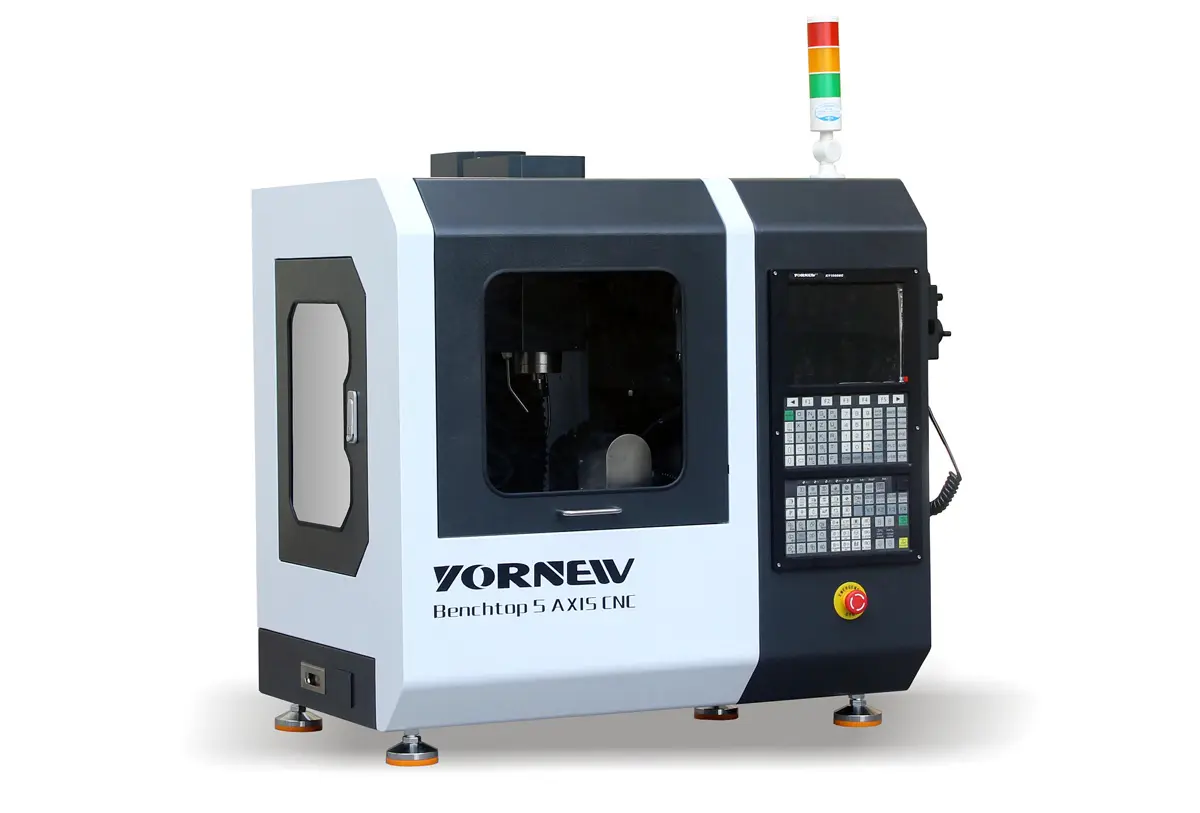

The MX220 Mini Benchtop 5-Axis CNC Mill is a compact yet versatile benchtop CNC mill. It adopts compact integrated structure, simple shape design, the highest space utilization, uses the best accessories and industrial CNC system, can cut metal aluminum alloy, 45# steel, G5 titanium, copper, etc. making them suitable for small workshops and businesses with limited space. Despite it smaller size, it offer a similar level of precision and versatility as it larger counterparts, making it an attractive option for a wide range of users.

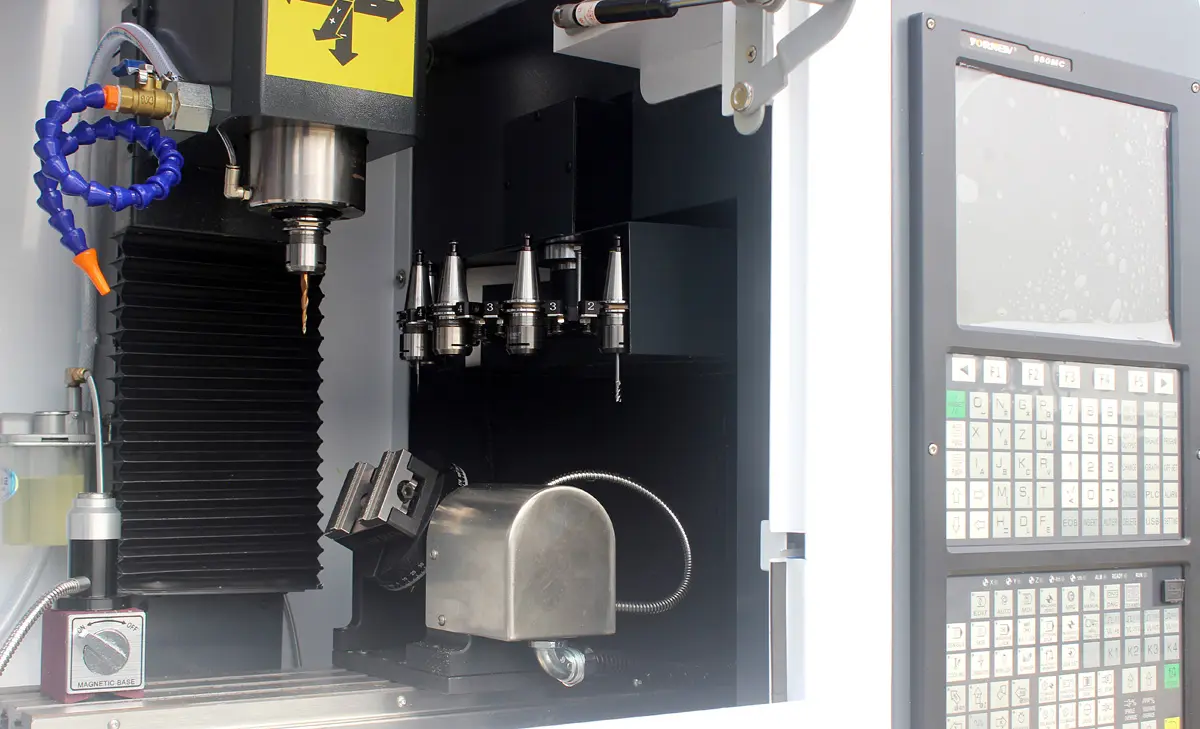

Invest in the MX220 Bench Desktop 5 axis CNC mill to have the ability to use larger, more industrial tooling. Achieve high levels of manufacturing in a convenient desktop unit.

The Advantages of MX220 Benchtop 5-Axis CNC Mill

1. Space-Saving Design: Mini 5 axis CNC mills are specifically designed to fit into tight spaces, making them suitable for small workshops and garages. Despite their compact size, these machines offer impressive capabilities for multi-axis machining, allowing small shops to take on a wide range of projects without the need for excessive floor space.

2. Versatility: Mini 5 axis CNC mills are highly versatile, enabling small shops to handle a variety of machining tasks with a single machine. Whether it’s producing complex 3D parts, creating intricate molds, or machining prototypes, these mills offer the flexibility needed to support diverse manufacturing needs.

3. Precision and Accuracy: Despite their small size, mini 5 axis CNC mills provide exceptional precision and accuracy. The ability to manipulate a workpiece from multiple angles allows for the production of intricate, high-quality parts with minimal margin for error. This level of precision is essential for small shops aiming to deliver superior products to their customers.

What types of materials can mini benchtop five axis CNC mills handle?

MX220 mini benchtop five axis CNC mills are capable of machining a wide range of materials, including metals such as aluminum, steel, and titanium, as well as various plastics, composites.

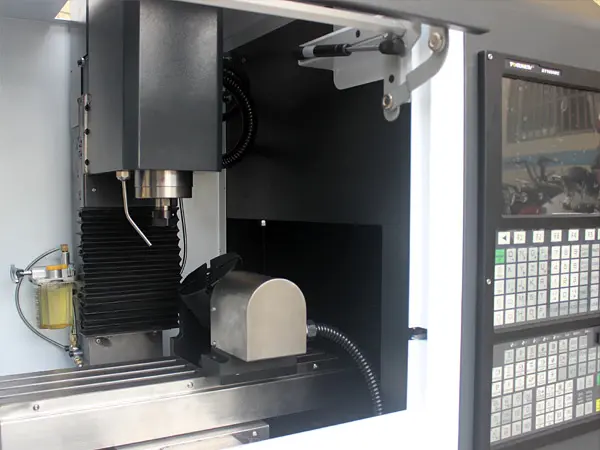

It can be used as a 3-axis CNC mill machine?

Yes,the 5-axis table adopted circular connectors to electrical box,remove the 5-axis table,it becomes a three-axis CNC mill machine,When you need to use the 5-axis function, into the circular connectors to the electrical box,it become a five-axis mill machine

Mini benchtop five axis CNC mills suitable for rapid prototyping?

Yes, mini 5 axis CNC mills are well-suited for rapid prototyping, thanks to their ability to accurately produce complex parts and prototypes with exceptional speed and precision.

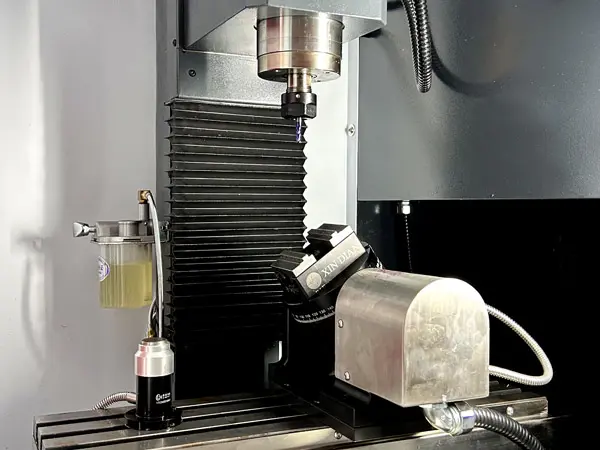

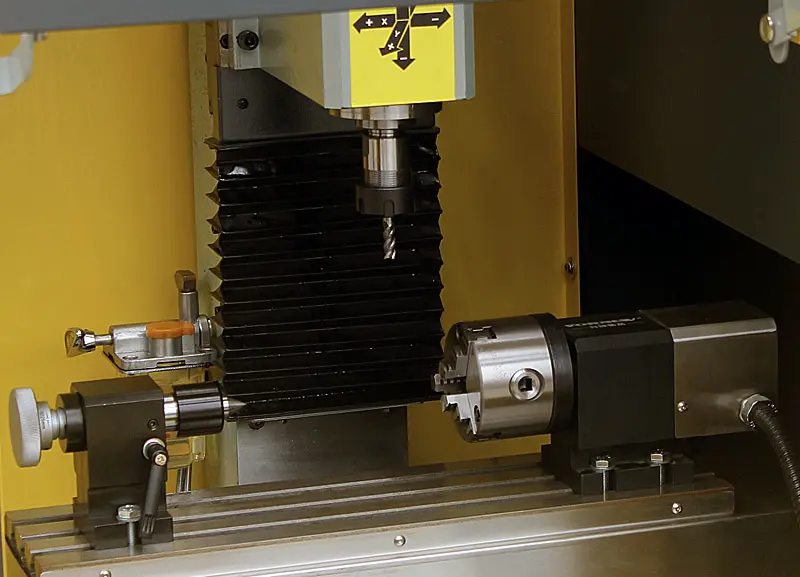

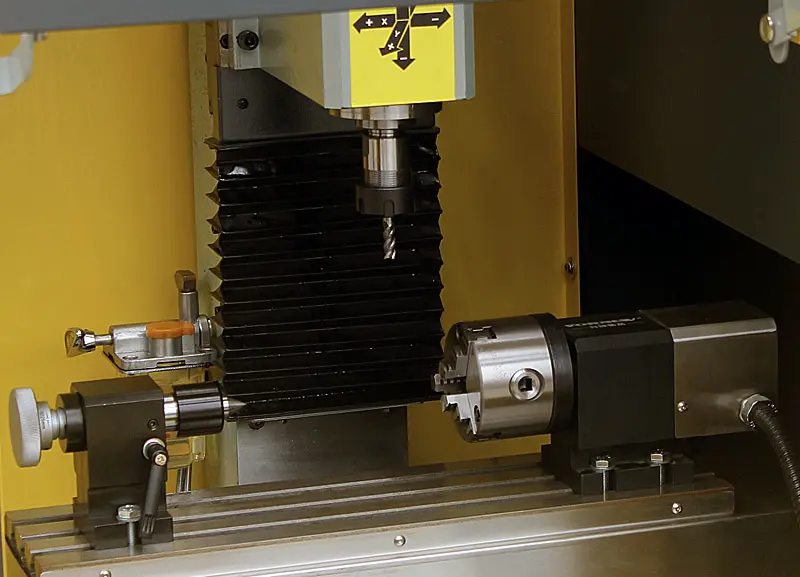

Optional 5th Axis

The production of complicated parts can be challenging,especially when precision, small tolerances and repeatability are important, a 5th axis allows machinists to fabricate up to 5 faces in a single operation. This makes the process highly efficient and precise. It also makes it suitable for creating complex structures and features with minimal setups.

Optional 4th Axis

4-axis CNC machining combines a rotational A to the three linear axes –X, Y, and Z. As a result, 4-axis CNC machining is ideal for machining parts at different angles with features like groves, undercuts, and curves.In contrast to index 4-axis CNC machining, continuous mode enables removing material with a spindle while a workpiece is being rotated about the 4th axis.

Machine tool body

Machine tool bod selection of high-quality casting materials,high-precision linear guide and ballscrews,semi-automatic lubricSation system,protect the rail life,Experience the pinnacle of precision, reliability, and longevity with our Small CNC Machine, featuring a high- quality casting materials for unwavering rigidity, high-precision linear guides and ball screws for unmatched precision, and a multi-line semi-automatic lubrication system for extended machine lifespan.

Efficient Cooling and Filtration

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools and spindle. With manual and automatic control options, our system adapts to your specific needs.

Do mini 5 axis CNC mills require extensive maintenance?

While regular maintenance is essential for any CNC equipment, mini 5 axis CNC mills are designed for ease of maintenance and typically require minimal upkeep, making them well-suited for small shops with limited resources.

FAQs

Q: What materials can be used with the mx220 mini benchtop 5-axis mill?

A: The mx220 mini benchtop 5-axis mill machine is suitable for a wide range of materials, including steel, non-ferrous metals, plastics, and more.

Q: Is the mx220 mini benchtop 5-axis mill suitable for small-scale production?

A: Yes, mini 5-axis milling machines are capable of producing complex parts and assemblies in small batches with precision and accuracy.

Q: How much space does a mx220 mini benchtop 5-axis mill need?

A: The mx220 mini benchtop 5-axis mill is designed to be compact and portable, making it suitable for small workshops and businesses where space is limited.

Q: Can the MX220 Mini Benchtop 5-Axis Mill be used for school education training?

A: The MX220 Mini Benchtop 5-Axis Mill is the perfect fit for high school and community college vocational training classes,their investment in learning the technology in the classroom will likely save time in training with their employer after graduation.